Started the re-build this week. The custom subframe and battery holder from Crowe Metal Co. are in so I can start to get a sense of how it will all come together. Still waiting on the engine rebuild from Shail’s in Langley, BC, Canada—I don’t want to do much more until I can work off its placement, but I can get everything ready.

First is a plan of attack. Been watching Boxer2Valve / Wunderlich America’s new, thorough and down-to-earth YouTube series on the refurb of a literal barn-find Airhead. It’s a good approach they have: just replace what they know and what they find to be wanting, leave the restoration part until after they get it running.

I like the main wrench’s style in the series. He’s careful to point out a particular process is just the way he likes to do something—not gospel—but he’ll explain why he does it that way. He’ll often show you the $300 special-purpose tool they sell to take your widget off once a lifetime but also the $30 homemade version you can make that works just as well. The videos are recorded in mostly real time, too—less cooking-show-cut-to-plating-and-it’s-perfect and more, “oh, we better tackle this thing now.”

If I had to quickly think of the order of operations for this rebuild I’d work in the following order:

- Sub frame on

- Engine in

- Fork and front wheel on

- Final drive on swing arm

- Final drive and swing arm in, rear wheel and brake, attach driveshaft to gearbox

- Carbs on

- Bench test full wiring

- Controls and handlebars, cabling, lighting

- Wiring harness (with intermittent tank- and seat-on tests)

- Brake bleeding

- Fenders and fairings

I realize now the main challenge has been visualizing and building and ordering replacement parts mostly in my head (and a giant spreadsheet), trying to get everything in place (in boxes) and then building all at once. Better would have been to build a bit, order, build a bit. Even better: ride it (it was running, sort of, when we bought it), fix a bit, ride, fix a bit…but for a couple reasons we didn’t: 1. We have some money to spend 2. We want this done in four months 3. Want to save on shipping 4. We’re doing a restomod, not just a restoration, so we’re still figuring what we want and what works 5. It’s my first full rebuild.

Here’s a simplified rundown of what has been ordered and arrived so far.

Electrical

- All new, simplified harness, with:

- m.unit Blue and m.button (for data collection, built-in solid state fuses (remove relays), simplified wiring, customizable controls)

- GXL wiring (solvent resistant, flexible but longer wearing than TXL) simplified to three colours, two gauges: red (power), green (switch signals), black (ground) and in 20AWG and 16AWG (and some 12AWG for direct battery connections)

- Deutsch connectors, fully waterproof, compact, standardized throughout bike, less faults, corrosion

- Dual wall (adhesive) heat shrink for weatherproofing all terminals

- Split loom (adds modularity for removing / adding components, troubleshooting)

- Voltage regulator (oem style, but slightly higher voltage, more compact)

- 12-cell LiFePo4 Antigravity-brand battery (compact, lightweight)

- All new tin-coated and brass terminals for existing hardware connections

- Grote LED headlight bulb and reflector, H4 plug-and-play

- Hella 500 Fog lamp

- 7″ vintage style headlight bucket

- Spark plugs and wires

- Ignition coil (Dynatec 3ohm dual tower)

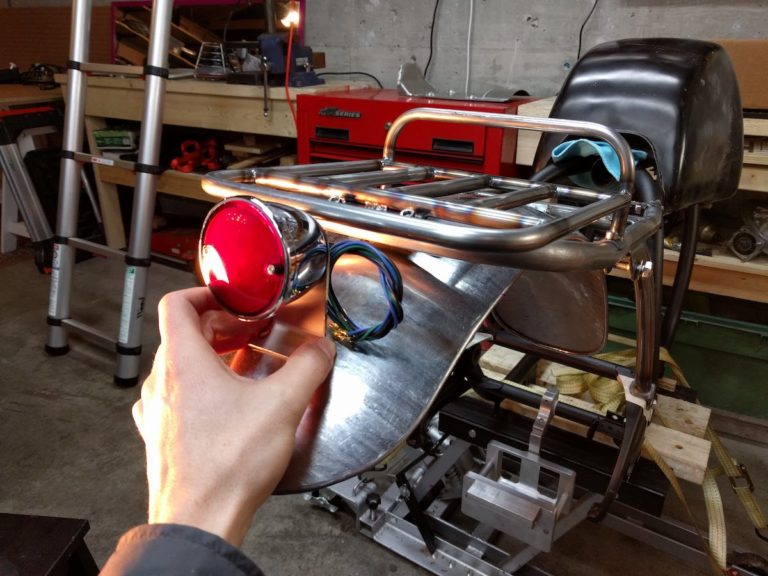

- Posh-brand blinkers and tail light

Controls & touch points

- Motogadget m.switches, 3-button (one on each side of the handlebar): momentary, most compatible with m.unit, minimal design

- Vintage style dual-pull throttle,

- Vintage-style cable-pull clutch and brake levers

- Scrambler-style handlebars, to be drilled (for the m.switches and minimal aesthetic)

- Custom seat upholstery (ostrich leather?) and foam on custom seat pan (by Crowe)

- LED charging lamp indicator w/ custom bracket

- Fog light toggle switch w/ custom bracket

- Motogadget motoscope tiny with custom bracket

- Footpeg and shift lever rubber

- Tank emblems

- Bar end mirrors

- DIY length throttle and clutch cable kits

Engine

- New valve seats (from leaded–>unleaded fuel)

- All new seals

- Deluxe carb kit

- Filters (air and oil)

- Cleaned and partially vapour blasted

Wheels

- Powder coated black (including spokes)

- New bearing in rear

- New rim strips and inner tubes

- New rubber (Continental?)

Frame, Brakes, Suspension

- Still looking for a DR650 front fork

- Custom front rotor, crowns, front fender, axle, steering adapater

- Rear shocks (Ikon)

- Powder coated black frame

- Stainless and polished hardware throughout

- New brake pads front and rear

- Front master cylinder overhaul (may need the new piston kit), new stainless brake hose

Leave a Reply